As technology continues to evolve, printer and copier consumables technology are not left behind. The printer and copier consumables industry has seen many advancements in recent years. These advancements have resulted in better performance, lower costs, and a more sustainable future for printer and copier users. In this article, we will discuss some of the 20 Cutting-Edge Inventions that Make Copy Printing Easier and More Efficient.

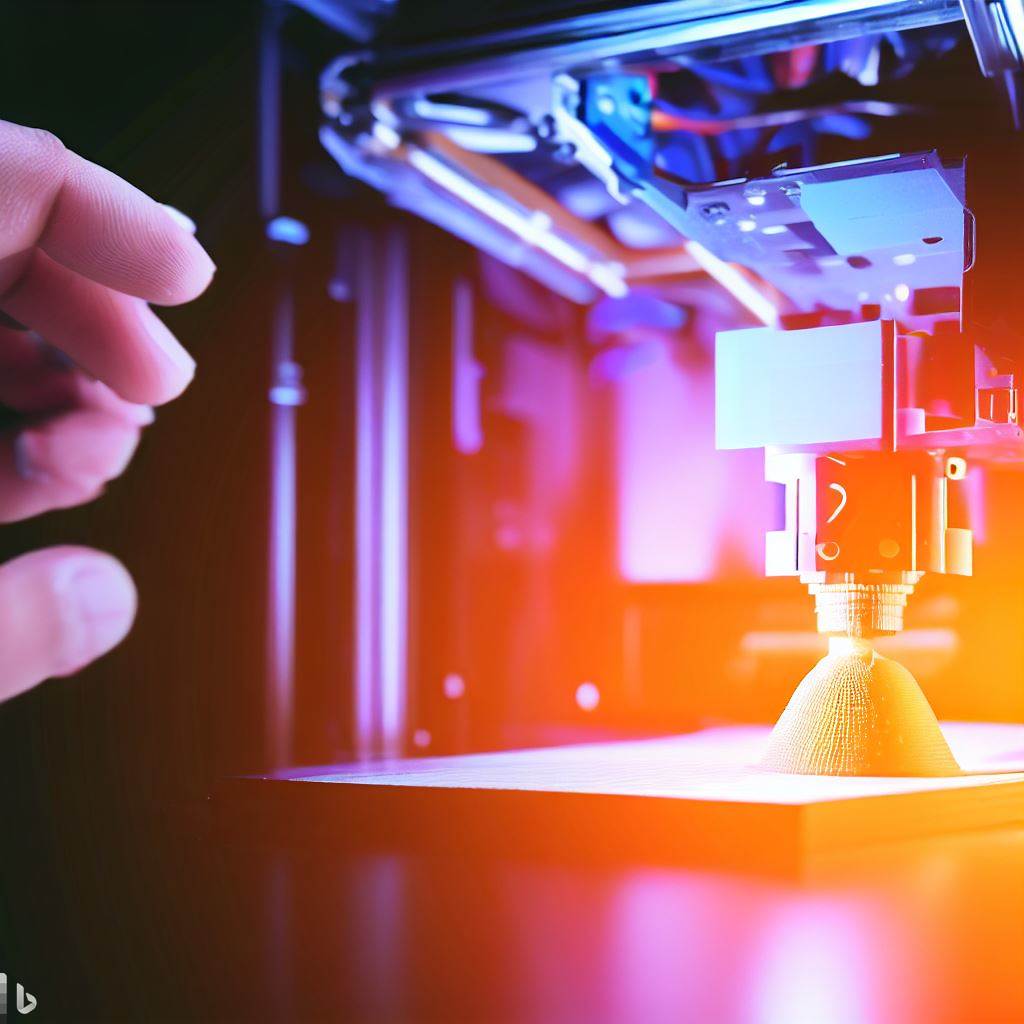

1.3D Printing – a process of creating three-dimensional objects from digital models by layering materials such as plastic, metal, and more. 3D printing is a manufacturing technology that allows for the creation of three-dimensional objects from a digital file. The process involves building an object layer by layer, by adding material (such as plastic or metal) onto a platform, based on a computer-generated design.

The 3D printing process begins with a digital 3D model that is created using computer-aided design (CAD) software or obtained through 3D scanning. The 3D printer then reads the digital file and lays down successive layers of material until the object is complete. There are various types of 3D printing technologies, including fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS), among others.

One of the main advantages of 3D printing is its ability to produce complex shapes and geometries that would be difficult or impossible to create with traditional manufacturing methods. Additionally, 3D printing allows for rapid prototyping and customization, making it a useful tool in a wide range of industries, including aerospace, automotive, healthcare, and architecture, among others.

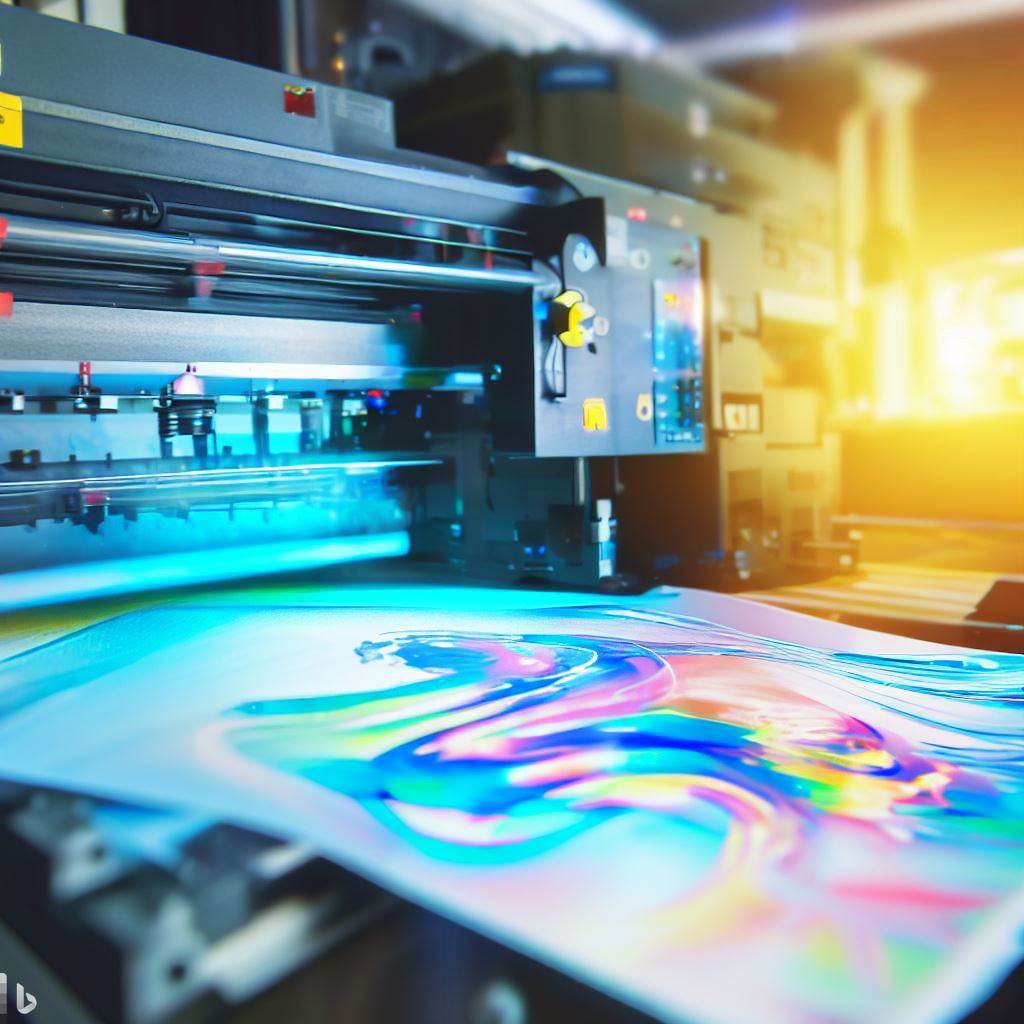

- Digital Printing – a method of printing from digital files directly onto various media using inkjet or laser technology.

Digital printing technology involves printing digital images directly onto various substrates such as paper, fabric, plastic, and metal using digital files instead of traditional printing methods like offset printing, letterpress, or flexography. Digital printing is accomplished through the use of advanced inkjet or laser printing technology that can accurately reproduce images with high precision, sharpness, and color accuracy.

The digital printing process starts with the creation of a digital image, which is then sent to the printer through a computer or other digital device. The printer then uses a series of nozzles to apply ink or toner onto the substrate, layer by layer, until the final image is produced. This technology allows for greater flexibility and customization, as it can accommodate small print runs and personalized designs without the need for printing plates or other specialized equipment.

Digital printing is widely used in a variety of industries, including advertising, packaging, textiles, and publishing, among others. Its advantages include cost-effectiveness, speed, and high-quality printing results.

- UV Printing – a type of digital printing that uses UV-curable inks and UV light to cure the ink, making it instantly dry and durable.

UV printing is a modern printing technology that uses ultraviolet light to cure (dry) the ink as it is printed onto a surface. The ink is made up of special pigments that react to the UV light and quickly dry and harden, resulting in a sharp, high-quality image.

This technology is commonly used in commercial printing for a variety of applications such as banners, posters, packaging, labels, and more. UV printing is known for its ability to print on a wide range of surfaces, including plastics, metal, glass, wood, and even textiles. One of the major advantages of UV printing is its high resistance to fading, scratching, and weathering, making it ideal for outdoor applications. Additionally, UV printing produces prints with vibrant colors and high-resolution details, making it a popular choice for high-end printing projects.

- Letterpress Printing – a traditional printing method that uses a raised surface to transfer ink onto paper or other materials.

Letterpress printing is a printing method that uses raised surfaces or type to press ink onto paper. It is one of the oldest printing techniques and was widely used before the advent of digital printing.

In letterpress printing, individual letters, numbers, and symbols are arranged in a composing stick and then locked into place. The composing stick is then used to create a printing plate, which is typically made of metal or wood.

Ink is applied to the printing plate, which is then pressed onto the paper. The raised surface of the type or image presses into the paper, creating a distinctive impression. This process can be repeated to create multiple copies of the same print.

Letterpress printing is known for producing high-quality prints with deep, rich colors and a tactile feel. It is commonly used for printing invitations, business cards, and other high-end printed materials. However, it can be a labor-intensive and time-consuming process, making it less practical for large print runs.

- Screen Printing – a printing technique that uses a mesh screen to transfer ink onto the surface of a substrate.

Screen printing, also known as silk screen printing or serigraphy, is a printing technique that involves creating a stencil or screen and then using it to apply ink onto a surface. The screen is typically made of a fine mesh material, such as silk or polyester, that is stretched tightly over a frame. Areas of the screen are blocked off with a stencil or emulsion, leaving open spaces through which ink can be pressed onto the printing surface. A squeegee is then used to push ink through the open areas of the screen and onto the printing surface below. Screen printing is commonly used for printing designs onto fabrics, such as t-shirts, as well as for printing posters, signs, and other materials. It can be used to print on a wide variety of surfaces, including paper, plastic, metal, glass, and wood. Screen printing is a versatile and durable printing technique that can produce high-quality results with a wide range of colors and designs.

- Sublimation Printing – a process of printing onto a special transfer paper, which is then heat-pressed onto the substrate, creating vibrant, high-quality images.

Sublimation printing is a digital printing technology that uses heat to transfer dye onto various materials, such as fabric, paper, metal, and ceramics. This process involves printing designs onto special transfer paper using sublimation ink and then heat-pressing the transfer paper onto the desired material.

Under high temperatures and pressure, the dye particles in the ink vaporize and penetrate the surface of the material, becoming a permanent part of the substrate. This results in a vivid, long-lasting, and high-quality print that is resistant to fading, cracking, and peeling. Sublimation printing is commonly used for creating custom clothing, signage, promotional products, and personalized gifts.

- Thermal Printing – a printing process that uses heat to transfer an image onto paper or other media.

Thermal printing is a digital printing process that uses heat to transfer an image or text onto paper. It involves a thermal print head that heats up a thermal transfer ribbon, which then melts ink or pigment onto the paper.

There are two types of thermal printing technology: direct thermal and thermal transfer. Direct thermal printing uses heat-sensitive paper that turns black when heated, while thermal transfer printing uses a ribbon coated with ink or pigment that is transferred to the paper through heat.

Thermal printing is commonly used in label printing, barcode printing, and receipt printing due to its fast and efficient printing speed, low noise level, and low maintenance requirements. It is also popular in portable and mobile printers due to its compact size and ease of use. However, thermal prints may fade over time and are sensitive to heat and light, making them less suitable for long-term document storage.

- Dye-Sublimation Printing – a printing method that uses a dye-sublimation printer to transfer dye onto a substrate, producing high-quality, long-lasting prints.

Dye-sublimation printing is a digital printing technology that uses heat to transfer dye onto materials such as fabric, plastic or paper. The process involves printing the desired image onto a special transfer paper using sublimation ink, which is then placed face down onto the material to be printed. Heat is then applied to the transfer paper, causing the ink to vaporize and bond with the fibers of the material, resulting in a high-quality, long-lasting print with vibrant colors and excellent detail. Dye-sublimation printing is often used for printing graphics and designs onto textiles, sportswear, signage, and other promotional products. It is also commonly used for printing photographs onto specialized photo paper.

- Offset Printing – a printing process that involves transferring ink from a plate to a rubber blanket, which then transfers the ink onto the paper or other substrate.

Offset printing is a popular printing technology used to produce high-quality prints in large quantities. It works by transferring ink from a metal plate to a rubber blanket, and then to the printing surface, usually paper. The metal plate is created with a reverse image of the design to be printed, and the ink is applied to the plate in the areas where the design is raised. The rubber blanket then transfers the ink from the plate to the paper.

Offset printing is known for its high image quality and color accuracy, making it a popular choice for printing books, magazines, newspapers, brochures, and other printed materials. It can also handle a wide variety of paper types and sizes, including coated and uncoated papers.

Offset printing requires specialized equipment and skilled operators, and it is typically used for large print runs of thousands or millions of copies. While it can be more expensive than other printing methods for small quantities, the economies of scale make it a cost-effective option for large-scale printing projects.

- Laser Printing – a printing method that uses a laser beam to transfer toner onto paper or other media.

Laser printing is a type of digital printing technology that uses a laser beam to produce high-quality prints. The process involves a laser beam scanning back and forth across a rotating drum, which is coated with a photosensitive material. The laser beam selectively charges areas of the drum, creating an electrostatic image of the printed material.

Next, toner particles, which are attracted to the charged areas of the drum, are transferred onto the paper through a combination of heat and pressure. The toner particles are then fused onto the paper using heat, creating a permanently printed image.

Laser printers are known for their high-speed printing and precise output, making them ideal for producing professional-quality documents, graphics, and images. They are commonly used in offices, schools, and homes, and are available in both color and black and white models.

- Digital Textile Printing – a type of printing that involves printing designs directly onto fabrics or textiles using specialized inkjet printers.

Digital textile printing technology is a process of printing designs or patterns onto fabric using digital technology. It involves the use of specialized inkjet printers that are designed to print directly onto fabric, rather than onto paper. The printer creates high-resolution images by depositing tiny droplets of ink onto the fabric. The ink is cured using heat or other methods, which ensures that it bonds with the fabric and remains durable even after washing.

This technology enables the production of high-quality, custom-printed textiles with vivid colors, sharp lines, and intricate details. It is a fast and efficient way to create small or large batches of fabric designs, without the need for complex screen printing or dyeing processes. Digital textile printing is widely used in the fashion and textile industries, as well as in home décor, signage, and other applications where high-quality printed fabric is required.

- Inkjet Printing – a printing method that uses small droplets of ink to create an image on paper or other media.

Inkjet printing is a digital printing technology that uses tiny droplets of ink to create images and text on a variety of materials such as paper, fabric, and plastic. The ink droplets are propelled onto the printing surface by a print head, which contains nozzles that can spray ink in precise patterns and sizes.

There are two main types of inkjet printing: thermal and piezoelectric. Thermal inkjet printing uses heat to create vapor bubbles that force the ink droplets onto the printing surface, while piezoelectric inkjet printing uses an electric charge to control the movement of ink droplets.

Inkjet printing is commonly used in home and office printers, as well as in industrial printing applications such as printing on packaging materials, textiles, and ceramics. The technology has many advantages, including the ability to produce high-quality images with fine details and vivid colors, as well as the flexibility to print on a wide range of materials.

- Large-Format Printing – a printing method that allows for printing on large sheets of paper or other media, commonly used for banners, posters, and other large-format graphics.

Large-Format Printing technology is a printing process that produces prints on a larger scale than traditional printing methods. This type of printing is used to create large-format graphics such as posters, banners, billboards, and other large-scale prints. Large-format printers typically use inkjet technology and are capable of producing prints up to several meters in width and length. The inkjet technology allows for high-resolution prints with vibrant colors, making them suitable for a wide range of applications. Large-format printing technology is widely used in the advertising, retail, and entertainment industries for creating eye-catching displays and promoting brands.

- Plotter Printing – a type of printing that uses a plotter, a specialized printer that uses pens to draw on paper or other media.

Plotter printing is a type of printing technology that uses a computer-controlled pen or other writing instrument to create high-quality, precise graphics and designs on a variety of materials, including paper, vinyl, fabric, and more. Plotter printers typically use vector-based graphics software, such as Adobe Illustrator, to create designs that are then sent to the printer for execution.

Unlike traditional printers, which use a raster-based approach to printing, plotter printers use a vector-based approach. This means that instead of printing a series of dots or pixels, the printer uses a series of lines and curves to create the final image. This allows for much greater precision and detail in the final product.

Plotter printers are commonly used in a variety of industries, including engineering, architecture, and graphic design. They are often used to create large-format prints such as banners, signs, and posters, as well as to produce precise technical drawings and schematics. Additionally, many plotter printers are capable of cutting materials as well as drawing on them, making them ideal for creating custom stickers, decals, and other adhesive graphics.

15.3D Scanning and Printing – a process of creating three-dimensional objects from scanned images or digital models.

3D scanning technology involves the use of specialized equipment, such as laser scanners or structured light scanners, to capture the three-dimensional geometry of physical objects. The captured data is then processed and converted into a digital model that can be edited, analyzed, or used to create a physical replica of the object.

3D printing technology, on the other hand, involves the use of a 3D printer to create physical objects from a digital model. The printer builds the object layer by layer, using a variety of materials such as plastic, metal, or even biological materials. Technology has revolutionized the manufacturing industry, allowing for the creation of complex and customized parts that would be difficult or impossible to produce using traditional manufacturing methods.

Together, 3D scanning and printing technologies have opened up new possibilities in fields such as product design, prototyping, art, architecture, and medicine. They have also made it possible for individuals and small businesses to create their own products, and for people to access customized solutions for a variety of needs.

- Automatic Duplex Printing – a feature that enables printing on both sides of a sheet of paper automatically, saving paper and reducing printing costs.

Automatic Duplex Printing is a technology that allows a printer to automatically print on both sides of a sheet of paper without requiring the user to manually flip the paper over. This feature can save paper and reduce printing costs. The printer uses sensors to detect when the first side has been printed and then flips the paper over and prints on the other side. Automatic Duplex Printing can be found in various types of printers, including laser printers, inkjet printers, and multifunction printers. It is also known as double-sided printing or two-sided printing.

- Wireless Printing – a feature that allows printing from a computer or mobile device over a wireless network.

Wireless printing technology allows printing without the need for physical cables or direct connections between a printer and a device that needs to print. Instead, it utilizes wireless networks such as Wi-Fi, Bluetooth, or NFC to establish a connection between a printer and a device.

To print wirelessly, a user typically needs to install and configure the printer on their network, and then connect to it through a compatible device, such as a laptop, tablet, or smartphone. Once connected, the user can send print jobs to the printer from anywhere within the range of the network.

Wireless printing offers several advantages over traditional printing methods, including greater convenience, flexibility, and mobility. It also allows multiple devices to connect to the same printer, reducing the need for multiple printers and reducing costs.

- Mobile Printing – a feature that enables printing from mobile devices such as smartphones and tablets.

Mobile printing technology enables the printing of documents, photos, and other types of content directly from mobile devices such as smartphones and tablets. With mobile printing, users can send print jobs to printers without the need for a wired connection, allowing for greater convenience and flexibility.

There are different types of mobile printing technologies, including Wi-Fi Direct, Bluetooth, and cloud printing. Wi-Fi Direct allows for direct communication between mobile devices and printers, while Bluetooth enables printing from devices that are in close proximity to printers. Cloud printing allows users to send print jobs from their mobile devices to printers that are connected to the internet.

Mobile printing technology has become increasingly popular as more people use mobile devices as their primary computing devices. It is widely used in businesses, educational institutions, and personal settings.

- Cloud Printing – a feature that allows printing from anywhere, using cloud-based services to send print jobs to a printer.

Cloud printing is a type of printing technology that allows users to print documents and other materials from any location, without requiring a direct physical connection between the printer and the device. This is made possible through the use of cloud computing, which enables users to store and access documents and files remotely and send print jobs to a printer located elsewhere.

In cloud printing, users send their print requests over the internet to a cloud-based print server or print service provider, which then routes the request to a printer connected to the network. The printer may be located in the same building or in a different city or country altogether. The user can then collect the printed output from the designated printer at their convenience.

Cloud printing can be especially useful in environments where multiple users need to share a single printer, or when users are on the move and need to print from a remote location. It also offers greater flexibility and scalability compared to traditional printing solutions, as users can easily add or remove printers from the network as needed, without requiring any physical reconfiguration.

- Interactive Printing – a technology that enables printed materials to be interactive, allowing users to access additional information or media by scanning a code or using a mobile device.

Interactive Printing is a technology that allows printed content to be interactive by embedding digital elements such as QR codes, augmented reality (AR) codes, and NFC (Near Field Communication) chips. This technology bridges the gap between the physical and digital worlds by allowing users to interact with printed material using their smartphones or other devices.

With Interactive Printing, users can access additional content, videos, product information, and social media links, or purchase products by scanning a code or tapping a device on the printed material. This technology can be used in various industries, such as advertising, education, packaging, and retail, to enhance the user experience and engage with customers.

Interactive Printing technology is still evolving, and new features and applications are continually being developed, making it a promising area for future innovation.

In conclusion, printer and copier consumables technology has come a long way in recent years. The latest developments in 3D printing, renewable and sustainable materials, smart technology, improved print quality, and mobile printing have made these consumables more efficient, cost-effective, and environmentally friendly. As a result, businesses and individuals can now enjoy a better printing and copying experience. If you’re looking to upgrade your printing and copying equipment, be sure to check out the latest innovations in consumables technology to find the right product for your needs.