Today no one is surprised by printers producing three-dimensional objects – there has been a variery of development approaches to the subject: glass printer, foam printer, even food printer, to name a few. However, craftsmen continue to find ingenious ways to implement known technologies. For example, Junior Veloso from Singapore, who stepped aside from the traditional method of printing in desiging his own 3D-printer.

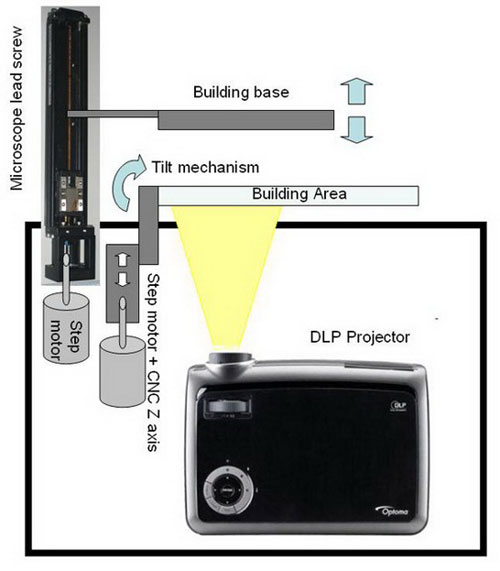

Traditional stereolithography usis a scanning UV-laser, which hardens liquid polymer layer by layer. The DLP-printer of the Singaporean operates in a similar manner, but it employs micromirrors-based video projector to expose the polymer layer by layer.

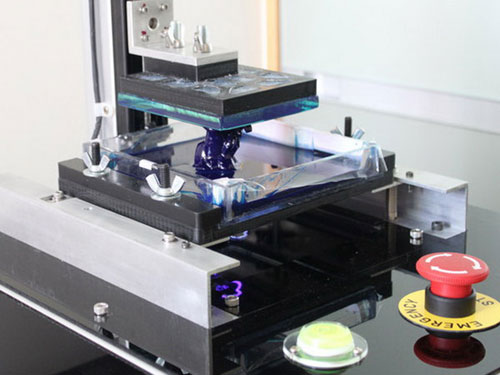

Such a design exhibits a single layer within 4-8 s, and it takes a few hours to build the entire object of multiple layers. In addition, the polymer should be opaque, or the effect of “shadowing” light passing through it would create a distorted shape.