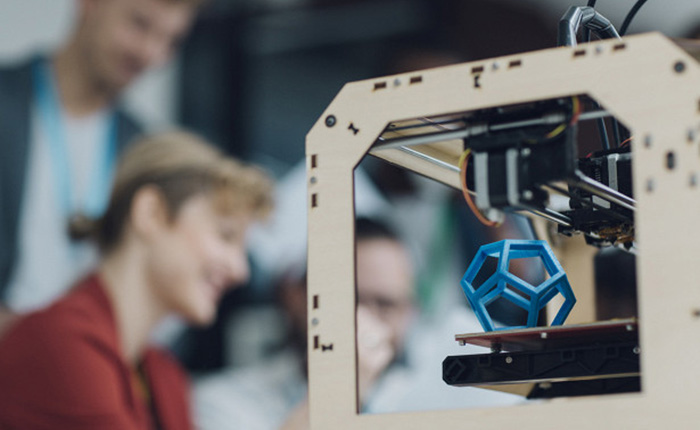

Additive technologies have been developing for years, but it is in 2017 that they made a breakthrough. MIT Technology Review made a list of 5 most amazing thing produced on 3D- printer.

1. Runnings Shoes

In April, Adidas launched mass-production of 3D-printed running shoes Futurecraft 4D, which would start selling in 2018. To apcoplish this, the company collaborated with Carbon, a startup from Silicone Valley. The implemented technologies make it possible to produce shoes 90 times faster. After the lauch of the second factory, Adidas will be able to produce about 1 million shoes a year.

2. Glasses, bevel gear and miniature replica of MIT dome

It’s not the object themselves, but the speed of their production that impresses. To make these thing, MIT reesarchers has used innovative technology that prints anything in minutes.

3. Parts for GE Aviation aircraft engines

In november, GE Aviation printed on its new 3D printer a combustor liner. The printer can make parts up to 1 meter in diameter using 1 kW laser. The building material used is metallic powder.

4. Steel

For many years engeneers could not solved a problem that is vital in 3D printing: plastic materials were not strong enough. In november, specialists from Livermore National Laboratry managed to produce a stainless stell AISI 316L that combines both plasticity and durability. According to the scientists, that enable to use stell 3D-printing technology in space, autoomobile and oil and gas industries.

5. Fast Printing of Metal Parts

Traditionally, 3D-printers use plastic materials, as it is afforable and easy to process. However, plastic if not suitable for everything, and working with more complicated materials like metal alloys is too expensive. Startup ‘Desktop Metal’ has developed a printer that make printing metal cheaper and speeds up the process 100x.